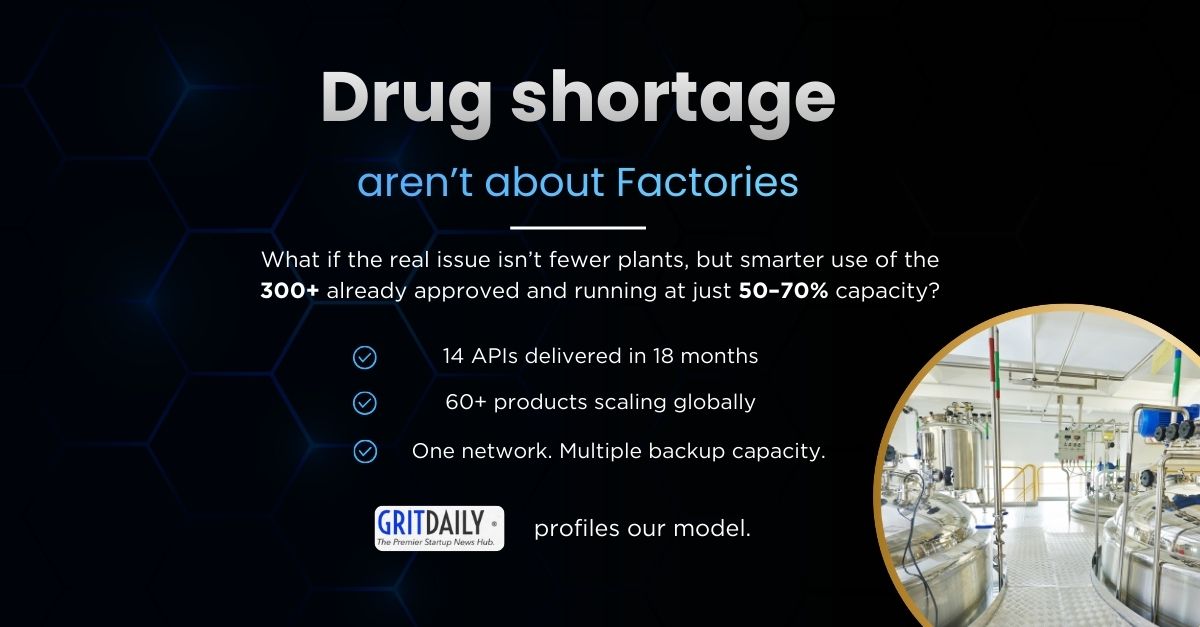

We are pleased to share that recent global industry discussions are increasingly highlighting virtual pharmaceutical manufacturing as a long-term solution to structural drug shortages across regulated markets. As global healthcare demand rises and supply chains face increasing complexity, flexible manufacturing orchestration is becoming critical to ensuring uninterrupted access to essential medicines.

Recent industry coverage by GRITDAILY has emphasized how network-driven pharmaceutical operating models are helping improve supply predictability, regulatory readiness, and faster response to market disruptions.

The Structural Reality Behind Modern Drug Shortages

Drug shortages are no longer driven only by production failures. Instead, they are often caused by structural supply chain rigidity, including:

- Underutilized global GMP manufacturing capacity

- Heavy dependence on single manufacturing sites

- Slow production transfer timelines during disruptions

- Regulatory and validation delays across facilities

Even when additional manufacturing capacity exists globally, traditional supply models often lack the flexibility to activate it quickly.

Why Traditional Capacity Expansion Cannot Solve the Problem Alone

Building new pharmaceutical manufacturing facilities is capital-intensive and time-consuming. New plants can take several years to become commercially operational due to construction timelines, technology transfer requirements, and regulatory approvals.

By the time new capacity becomes available, therapy demand and market conditions often change, creating new supply gaps.

The Shift Toward Virtual Manufacturing Networks

Virtual pharmaceutical manufacturing models focus on coordinating existing global manufacturing infrastructure rather than building new facilities. This enables dynamic production allocation based on demand, regulatory approvals, and available capacity.

Key advantages include:

- Faster response to supply disruptions

- Reduced dependency on single-site manufacturing

- Access to idle but compliant manufacturing capacity

- Improved global supply continuity

Maintaining Quality and Regulatory Compliance at Scale

Modern virtual manufacturing networks operate using standardized quality systems, centralized documentation frameworks, and real-time compliance monitoring. This helps maintain consistent regulatory visibility and product quality across distributed manufacturing environments.

Advanced digital monitoring and data-driven compliance frameworks allow manufacturing deviations to be identified and addressed quickly, reducing risk across the supply network.

Impact on Healthcare Systems and Patients

For healthcare providers and patients, flexible manufacturing networks improve treatment continuity, reduce shortage risks, and ensure consistent medicine quality regardless of production location.

As chronic disease burden rises globally, supply chain resilience is becoming as critical as pharmaceutical innovation.

Future Outlook

The pharmaceutical industry is moving toward a model where supply chain intelligence and network connectivity define competitiveness. The future of pharmaceutical resilience will depend on how effectively global manufacturing infrastructure can be coordinated rather than simply expanded.

As digital manufacturing orchestration and regulatory integration improve, virtual pharmaceutical operating models are expected to play a larger role in supporting global medicine accessibility.

Frequently Asked Questions

1. What is virtual pharmaceutical manufacturing?

Virtual pharmaceutical manufacturing is a network-based model that coordinates multiple GMP-approved manufacturing facilities through centralized regulatory, quality, and supply chain systems.

2. How does this help reduce drug shortages?

It allows production to shift between facilities when disruptions occur, ensuring continuous medicine supply even if one manufacturing site stops production.

Why is manufacturing flexibility important for global healthcare?

Flexible manufacturing allows healthcare systems to respond faster to demand spikes, regulatory disruptions, and supply chain challenges while maintaining consistent product quality.